03 May 6 Things To Consider To Choose The Right Weighbridge Supplier

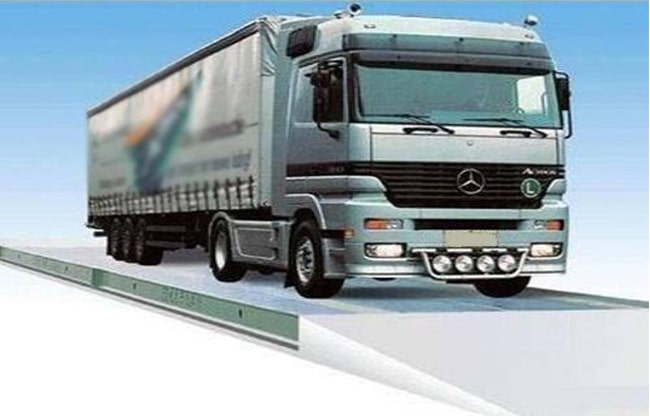

Weighbridges or truck scales are used for legal-for-trade freight weighing of vehicles or for loading goods on the plates, such as bulk cargo or livestock. The main components of the weighbridge, namely, foundation, platform, load cells, terminal, and cables, work together to weigh readings when the vehicles mount on to the scale.

Weighbridges are mainly used for weighing heavy equipment vehicles or rail containers where the movement of goods is done with the help of trucks. It enables industries to get the exact figures to maintain the goods inward and outbound movement of goods. It helps determine the maximum permissible weight, load capacity, age, and axle configuration of the vehicle to maintain safety on the road. Using a weighbridge ensures that the loaded vehicle will not put the driver and fellow cars at risk.

Weighbridges are long-term investments, and it plays a vital role in a business transaction. It helps the enforcement agency to identify if the vehicle is compliant with the regulatory protocols. Hence, if your business is dependent on weighbridges to carry out various operations, you need to choose a weighbridge that is tested and calibrated correctly. The weighbridge supplier should ensure that it is built according to the recognized ISO standards.

Six things to consider while selecting a weighbridge supplier:

Manufacturing Process

Ensure that the weighbridge has been manufactured according to standard regulatory protocols. These standards intend to chiefly cover the technical provisions for more extended durability and proper functioning.

Support

Weighbridges require additional support during their lifetime to ensure continued accuracy and maximization of product functioning. Select a vendor with user-friendly service plans to maximize uptime and reduce downtime. They can also provide you with nationwide service cover at the affiliated service station so that you can bring it back to service quickly.

Knowledge And Experience

You need to take the supplier’s experience, technical knowledge, manufacturing facility, and service infrastructure into consideration to choose the right weighbridge supplier. Ensure that they have the right workforce to support your weighbridge.

Compliance

In particular, working conditions, petrochemical facilities, dust, gases, and fumes can accumulate in the area beneath the weighbridge. It can lead to a potentially explosive atmosphere. Hence, the weighbridge should comply with security protocols that are prescribed for operations in the hazardous zone.

Automation

You can also for automation feature in the weighbridge system to automate the processing of vehicles without a dedicated operator. It enables you to minimize operating costs and extend hours of availability.

Additional Features

You can also look for additional features like RFID (Radio Frequency Identification), boom barriers at entry and exit of weighbridge, sensors for the vehicle position, camera surveillance at weight recording, variable message displays or traffic lights, and voice guidance for managing traffic flow. It can help you combat weighbridge theft and fraud to monitor, organize, and collect data in an improved manner.

To Conclude:

You can look for these features while selecting your weighbridge. The weighbridge supplier should provide you with the best solutions to maximize your business efficiency.

No Comments