15 Mar What Is Concrete Weighbridge And Its Features

Concrete weighbridges have a high demand in the marketplace. Weighbridges find varied uses in the industries, and this variant provides leverage to the sectors to quickly weigh the empty or loaded vehicles. Concrete weighbridges require minimal maintenance, and it is an ideal choice for long term investment.

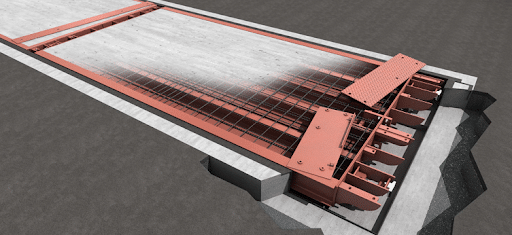

The outstanding weighing performance of concrete weighbridges makes them suitable for weighing truck loads in foundries and construction sites. Several of its characteristic features like high strength, flexibility in design, load-bearing capacity, and durable operational life have increased the demand for concrete weighbridge. The installation process of a concrete weighbridge is relatively easy.

You can avail of it at affordable rates for your business needs. Because of the concrete frame, these weighbridges can endure the harsh climate and rough working conditions. Concrete weighbridges can have either a surface mounted scale or pit mounted scale. The type of scale you want to install will depend on the availability of space.

Here are a few of the critical features of a concrete weighbridge.

· Concrete weighbridges have a rust-proof finish. It is corrosion-resistant and has excellent fabrication. Its corrosion-resistant properties are achieved by passing the weighbridge through shot-blasting and epoxy paint coating levels.

· Concrete weighbridges use superior quality steel, which gives them a more vital load-

bearing capacity. It also has a robust sectional efficiency.

· During the manufacturing stage, the design is thoroughly tested to build an excellent quality weighbridge. MIG welding, plasma cutting, shot-blasting, epoxy paint coating, and finishing are performed to match the desired quality standards. The concrete platform’s quality is kept under check to adhere to the middle of the required load-bearing capacity.

· Concrete weighbridges have a lower installation price as compared to steel platforms.

· The steel frame of the weighbridges undergoes heavy stress and strain, negatively impacting the load cells. However, in the concrete weighbridge case, the concrete platforms’ design support allows the load to be transferred vertically. The welded module of this weighbridge is fully ensured by using high welding wires. These wires provide rigidity to the concrete platforms.

· The stress and strain that develop on the steel frame are due to the cantilever effect. This can lead to errors in the calculation of the data. In concrete bridges, however, these are null.

Application Areas Of Concrete Weighbridge

Concrete weighbridges are robust in strength and have more extended durability. Due to easy installation and minimal maintenance, it is in high demand. It is designed for a highly concentrated load. The tension forces are handled by the high-strength steel structure, which is used below the concrete. The design support of these weighbridges provides inherent strength, overload protection, along with accuracy and high reliability. This makes the concrete weighbridges suitable for weighing in foundries and construction sites. It can also be used for weighing shipment. It is also helpful for proof tests and destruction tests.

Moreover, it can also be used to prevent the overloading of trucks or vehicles. Concrete weighbridges are also used for drag force measurement.

To Conclude:

Concrete weighbridges have a wide range of applicability. Available at reasonably affordable costs, these weighbridges have a remarkable weighing capacity. The concrete decks are sturdy, and these weighbridges have easy installation and management procedures.

No Comments